Radiation Shielding & Insulation Group

Introduction

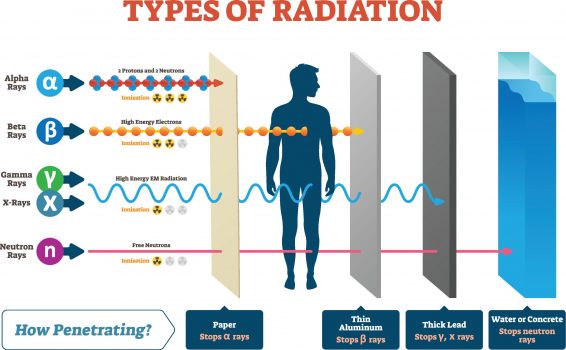

X-Ray is a hazardous type of ray that we must protect people against. As we know, lead sheets (lead rolls), lead glass, and lead doors are used to isolate x-ray radiation. Therefore, KarZah, Advanced Materials, provides the work and materials required for x-ray shielding in the Radiation Shielding and Insulation group. Our work includes the lead lining of x-ray imaging device rooms, x-ray baggage inspection machines, and radiology examination centers and laboratories.

Materials Used for Radiation Shielding

Our company provides many types of lead materials used in the shielding and insulation process, including:

Lead Sheets (Lead Rolls)

We provide our clients with high purity lead sheets of various thicknesses 1, 2, 3, 4, and 5 mm. As for the dimensions of the sheets, we provide lead sheets in the following sizes:

- 1000 × 2000 × 2 mm

- 1000 × 2200 × 2 mm

- Different sizes can be available by special requests.

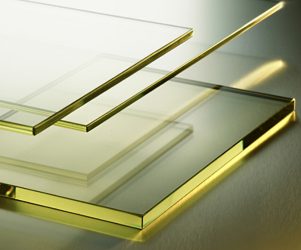

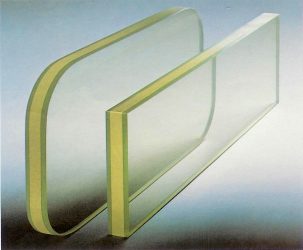

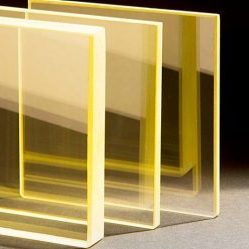

Lead Glass (Leaded Glass)

Lead glass is a type of leaded glass used in radiation shielding. We supply and install lead glass of required dimensions, thicknesses, and specifications. We install lead glass in the doors and partitions behind which x-ray technicians sit to operate x-ray imaging machines. It is important to remember that barriers in x-ray theaters need shielding too.

Lead Doors (Leaded Doors)

Leaded doors or leaded doors are doors that are insulated with lead sheets for radiation shielding. We supply the following types of lead doors:

- Wooden doors with wooden frame

- Wooden doors with steel frame

- Steel doors with steel frames

Lead Accessories

We supply all accessories and supplies for radiation shielding and insulation required in hospitals and in the medical sector.

Uses and Applications of Lead Sheets

Lead sheets (Lead Rolls) have many uses. We specialize in the following ones:

Lead Lining and Lead Shielding of X-Ray Rooms

One of the most critical lead sheet applications carried out by our company is the shielding of X-ray rooms. It is crucial to know that failure to properly insulate x-rays can cause harm to people in that place. This can pose a threat to technicians, doctors, employees, and even patients. Therefore, it is necessary to prevent x-ray leakage to undesired spaces or unnecessary people exposure to x-ray.

We call this type of work x-ray room shielding, x-ray room insulating, or x-ray room lining. Our team performs this work in hospitals, clinics, x-ray laboratories, or in places where the following imaging devices are located:

- X-Ray Machines

- Panoramic X-Ray Machines or Panoramic Radiography

- Mammograms

- CT Scan (Computed Tomography Scan)

- CAT Scan (Computerized Axial Tomography Scan)

Shielding of X-Ray Baggage Inspection Machines

We use lead sheets to insulate x-ray devices and x-ray machines used for baggage inspection and luggage inspection. These machines are generally available in airports, border offices, shopping malls, hotels, government sectors, and business sectors. Professional shielding of these machines provides the necessary protection from any accidental harmful leaks to the surrounding areas and people.

Radiology Examination Centers and Laboratories

To provide protection against radiation in these locations, we usually install lead sheets on the walls, floors, and ceilings. This shielding or lining process should comply with the design specifications indicated for the place. After installing the lead sheets on the walls or ceilings, we install wooden boards or gypsum boards to cover them. In the case of floors, we can start the tiling work or the parquet installation after the shielding process is complete.

Execution Steps of Lead Shielding (Lead Lining)

Our team performs the work in the following general sequence:

- We contact the client’s technical department for a detailed scope of work and material specifications

- We review drawings and take actual as-built site dimensions

- Our team makes lead sheets and other materials for the site

- We carefully unroll and straighten the lead sheet (lead rolls) to get rid of bends without damaging the sheets

- We apply adhesive materials on the walls and ceilings and then affix the lead sheets to the required locations

- Secure the installed lead sheets with nails and screws then fix small lead patches to the top of the fasteners. The function of the lead patches is to ensure that the radiation does not leak from the fasteners’ place. In the drywall system, we fix the lead sheets on wooden boards first, then fix the wooden boards to the walls.

- For floor shielding, we fix the lead sheets on the ground and then add a protection layer on the top.

- We install the tiles, the parquet, or other types of floors with the correct technical methods. Pay great attention not to damage the lead sheets or affect the system integrity during installation.

- Install the lead doors (the doors shielded with lead sheets). We perform the door fabrication and shielding at the factory.

- Install lead glass in the doors and partitions behind which the x-ray imaging technician sits inside the control room

- After completing the shielding of the room, examine the room for radiation leakage. Ensure that results comply with safety standard levels. Specialized institutes and companies, licensed by the government, perform this inspection procedure and provide compliance certificates.

- After obtaining compliance certificates, we proceed to the final stage. We cover the lead sheets with gypsum boards, wood boards, or other boards, as per technical specifications.

Site Condition before Starting Lead Shielding Process

- Finish all civil and electro-mechanical work at the site

- Walls, ceilings, and floors should be ready to start the shielding work

- The place is clean, and electricity for lighting and electric tools are available at the site

KarZah Installation Team

Due to the sensitivity of the lining and shielding products and the need for precision in their installation, KarZah has trained a team of technicians and specialists to perform this type of job. Moreover, our team has qualified to complete the cladding and finishing work required after shielding as per technical specifications.

The completion of the cladding and finishing work by our team ensures work integrity inside shielded rooms. This will reassure our clients that shielding materials are intact, and the lining is professionally completed.