Rubber Flooring Group

Introduction

KarZah, Advanced Materials presents in this group an essential flexible type of flooring: Rubber Flooring. This group includes natural rubber, synthetic rubber, EPDM floor, SBR and cast-in-place solution. In response to the rapid increase in requirements and stricter regulations on personal safety, the production and usage of this floor have begun. Because people are vulnerable to falls, rubber’s properties are helpful for effectively mitigating fall effects.

Origin of Natural Rubber

Important to realize that manufacturers extract natural rubber from Brazilian Hevea trees, which are present in the Amazon rain forests. Among rubber’s premium properties are its high elasticity, strength, and resistance to tearing, cutting, and bending at low temperatures.

Rubber Recycling

Preserving rubber is vital as it is a natural resource. Therefore, many systems are in place to recycle it. Additionally, since tires are a primary source of used rubber, many factories recycle it and supply it to many applications. The stages of its recycling are:

- Collection of rubber waste

- Isolation of the rubber from the other materials

- Cutting the rubber into granules

- Packing it in bags for sale

Moreover, because of the increase in demand and perpetual rubber scarcity, the need to manufacture rubber alternatives arose. Consequently, EPDM (Ethylene Propylene Diene Monomer), which has similar properties to natural rubber, was synthesized.

Rubber Flooring Classification

Classification of Rubber Flooring According to Nature of Material

Below are rubber floor classifications based on the type of main raw material used:

Virgin Natural Rubber

Virgin Natural Rubber is made of natural rubber without any additives and can have the color modified upon request. KarZah supplies natural rubber floors from reputable companies.

Recycled Rubber

Initially, this type undergoes sorting, refining, then cutting into small pieces as per specs. It is worth knowing that tire recycling is one of the primary sources of obtaining this type of rubber. Due to the black color of tires, we call this type of material SBR (Solid Black Rubber).

Synthetic Rubber

This type of rubber flooring consists of granules of colored EPDM, mixed with hard rubber granules.

Classification of Rubber Flooring According to Shape of Product

We classify rubber floors according to their shape into four types:

Square and Interlock Rubber Tiles

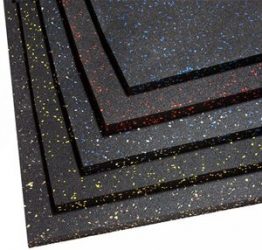

They are black and consist of one or two layers. If the tile is in more than one layer, then the lower comes in SBR. However, the upper layers are colored (green, red, or blue).

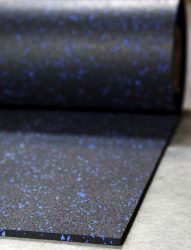

Rubber Rolls

Rubber rolls can be manufactured from Virgin Natural Rubber, SBR, or EPDM.

Cast-in-Place Rubber Floors

This type is poured in place using SBR.

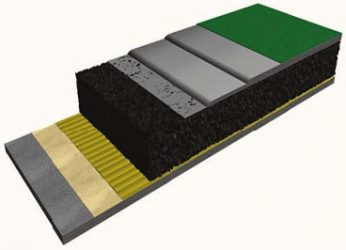

Layered Rubber Floors

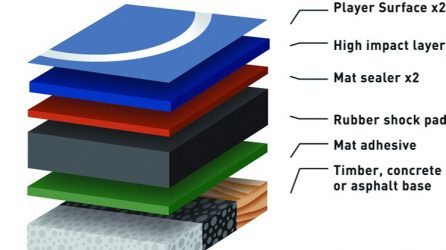

We usually use this type of flooring for indoor sports courts and stadiums. It is important to know that the base layer is made entirely of SBR, like SBR tiles, rolls, or casting. Finally, a polyurethane or acrylic top layer is applied.

Classification of Rubber Flooring According to Product Composition

We classify rubber floors according to product composition and product application to the following five types:

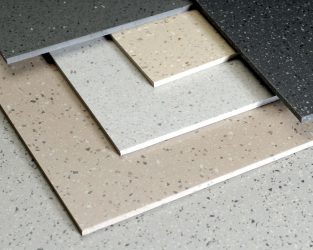

Flooring Made of Solid Black Rubber Granules SBR

These floors consist of rubber granules mixed with polyurethane glue and colored materials. Square tiles are of different sizes and thicknesses. They also come as a cross interlock. Among the most primary advantages of this type:

- Used internally and externally

- There are several colors (blue, red, green, and black)

- Withstand external factors of heat, sun, water, and moisture

SBR Rubber Casting Floors

These floors consist of rubber granules mixed with polyurethane glue and colored materials. Rubber is mixed mechanically at the installation site with different components, and then the mixture is poured into a machine. The machine spreads the rubber mixture on the floor with specific thickness and density according to specs. This type of rubber is similar to the previous type (SBR), but it differs in its application. Furthermore, the method of installing and applying this type is easier and faster than laying tiles one by one. Among the most valuable advantages of this type:

- Used internally and externally

- There are many colors (blue, red, green, and black).

- Endures external factors from heat, sun, water, and moisture

- Ease and speed of application and installation on-site, especially for large areas

Gym Club Polyurethane Rubber Flooring

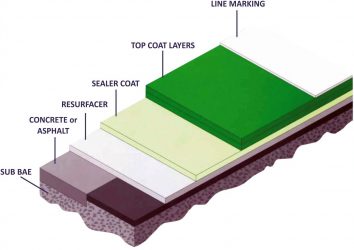

These floors consist of a base layer of SBR with a thickness of 8 mm, mixed and applied mechanically with polyurethane glue on site. Alternatively, we can position an SBR of 8 mm rolls on site. We deploy a primer layer to ensure that layers bond together well. A sealing material fills the gaps and levels the surface. We pour a self-leveling layer of polyurethane with a thickness of 2 mm. We coat the surface with anti-corrosion substances to ensure that surface does not corrode in the long run. This substance provides UV protection, too. In the final stage, we paint the playground lines as per specs.

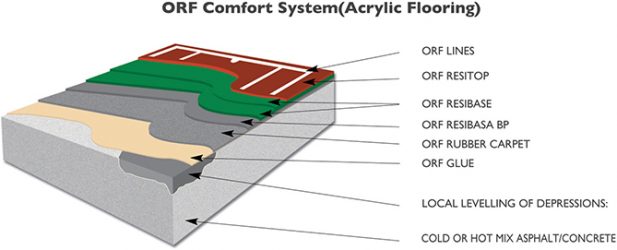

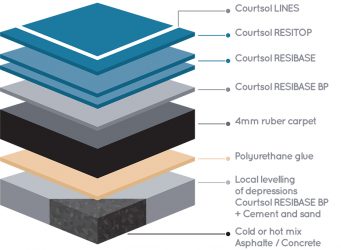

Acrylic Rubber Floors Acrylic System

KarZah provides several types of Acrylic rubber floor systems. These floors consist of a base layer of SBR with a thickness of 8 mm, mixed and applied mechanically with polyurethane glue on site. Alternatively, prefabricated 8 mm SBR rolls can be placed on site.

We deploy a primer layer to ensure that layers bond together well. A sealing material fills the gaps and levels the surface. Then, we cast the finished acrylic layer with a thickness of 2 mm. In the final stage, we make stadium lines according to the specs of each stadium.

EPDM Rubber Flooring

Roller rubber floors are composed of black rubber granules (SBR), mixed with polyurethane glue, and some colored industrial EPDM granules added in a percentage ranging between 15-20% of the total components. This type of synthetic rubber comes in various thicknesses, and its density varies between 850 – 900 kg / m³, which makes it distinguished by its high shock resistance. Among the most outstanding advantages of these floors:

- Used internally and externally

- There are many colors (gray, blue, green, orange, yellow)

Applications of Rubber Flooring

Natural and synthetic rubber is installed on floors and walls as a type of shock protection system. Rubber floors are generally suitable for the following areas:

- Indoor and outdoor gym floors

- Public garden floors, courtyard floors, university and school stadium floors

- Recreation places flooring

- Outdoor flooring

- The floors of walking and sports places

- Indoor and outdoor children’s playgrounds and walls

- Flooring, home gardens

- Floors and walls of health clubs and bodybuilding centers

- Ocean floors, swimming pools, and walkways

There are also specific applications of this category, the most important of which are:

- Electrical insulating matting is one of the mandatory safety requirements for a major part of electric applications. It protects workers against electrical shocks caused by accidental touch to live uninsulated elements or in case of electrical leaks. They are used when operating:

- Electrical workstations

- Live LV-HV switchgear

- Switchboards

- Substations

- Transformers

We supply electrical insulating mattings that comply with the following standards:

- Electrical Rubber Mats, IEC 61111

- Switchboard Mats, ASTM – D178

- Electrical Safety Mats, AS/NZS 2978

- Equestrian, in horse stables facilities. The rubber floors give the horses a soft level and help them protect against joint and cartilage infections.

- Floors, walls, and ceilings of military and private shooting ranges. To adequately soundproof shooting ranges, we install a particular type of solid rubber granule SBR tiles of 30 – 50 mm thick. These tiles protect the walls from damage due to shooting, too.

Rubber Flooring Features

Rubber flooring has many features:

- Shock resistant

- Fall protection

- Anti-slip

- Bulletproof if thick and high in density

- Ease of installation

- Ease of cleaning

- Heat and sound insulators

- It gives an aesthetic view of the land upon installation

- Rubber floors work for walls internally and externally

- Does not need accessories for mounting, except for glue